X-ray inspection of die-casted components

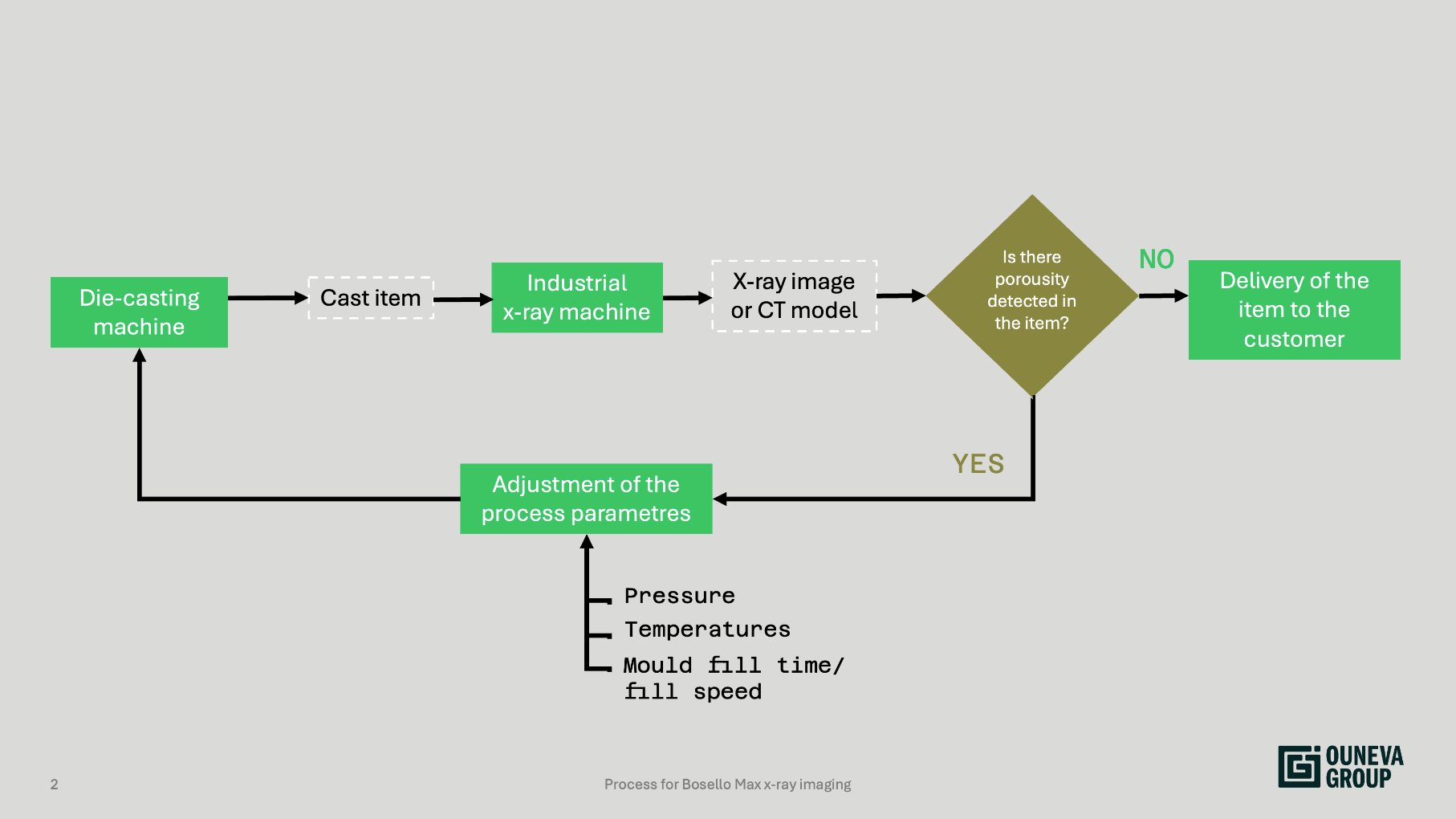

In February 2025, Alsiva took a big step forward in quality assurance by investing in an x-ray inspection machine. This machine will be used in our production process for performing quality checks before mass production begins and conducting random inspections during manufacturing.

The x-ray machine enables us to examine the internal structure of cast products without breaking them apart. For instance, it easily detects porousity, a common defect in cast components. With product-specific automatic cycles, inspections are fast, efficient, and highly accurate.

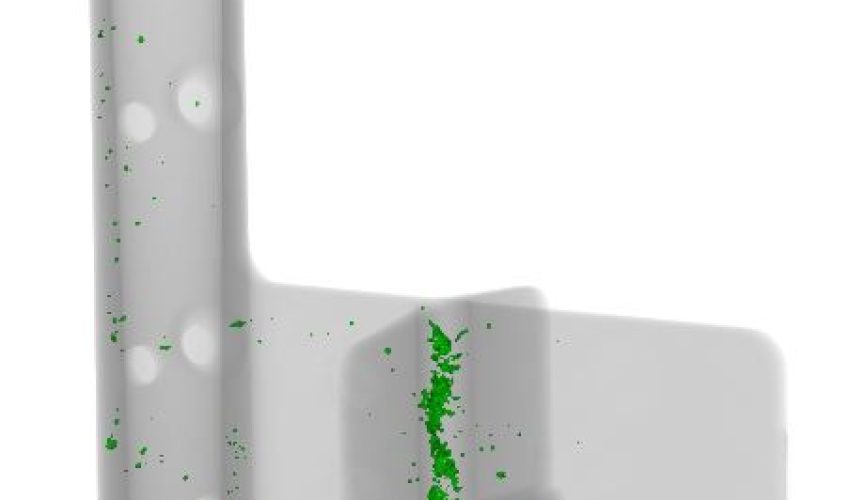

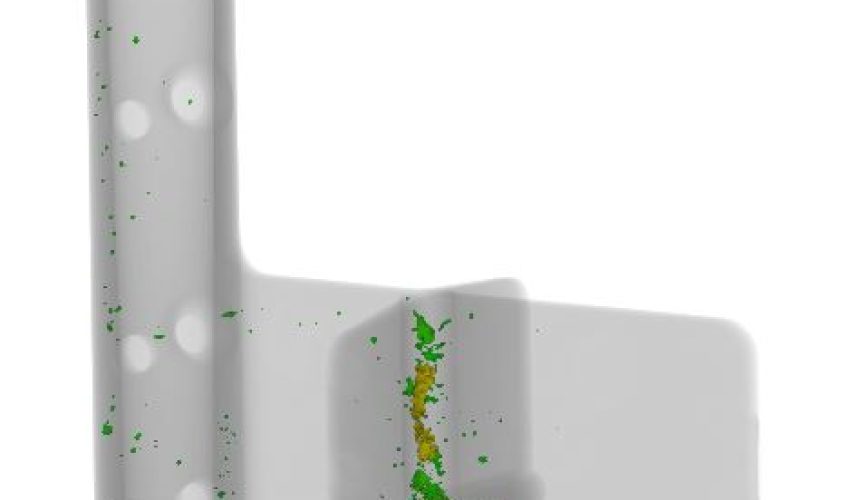

In the photos below, porousity is detected by the x-ray machine. In the photo on the left, porous areas are dyed with green colour. On the right, porous areas are dyed with different colour indicating the sizes of the pores.

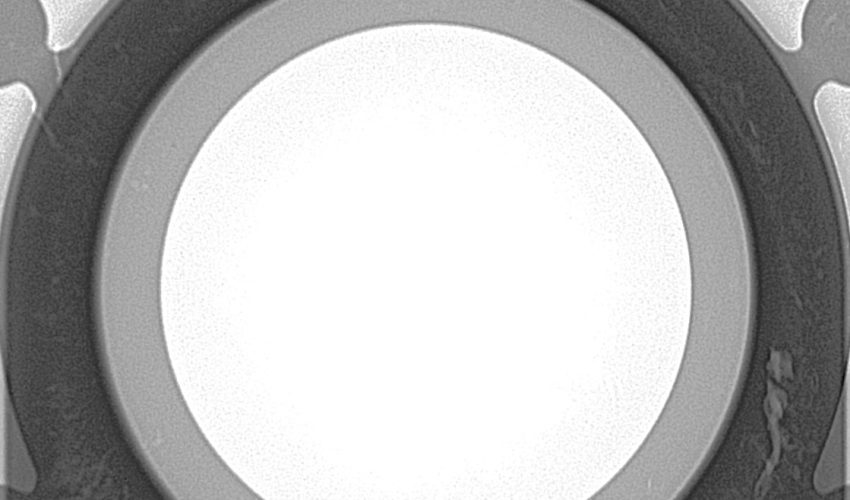

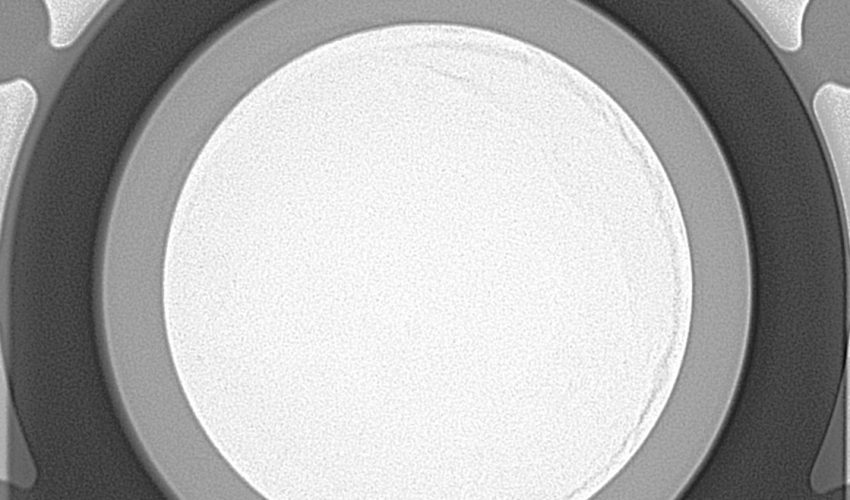

Above on the left is a product that is porous and did not pass the quality control. On the right you will find the same product after adjusting the process parametres. No porousity is detected, which means the product passes the quality control and mass production can begin.

By analyzing initial samples, we can fine-tune our casting machine settings before full-scale production starts. This proactive approach boosts efficiency and eliminates the need for manual breakdowns. Catching quality issues early also helps us minimize excess material. Although we recycle all surplus in-house, reducing waste remains a top priority. For our customers, the benefit of the x-ray inspection process can be seen clearly due to the improved quality in the beginning of the manufacturing process. Thanks to the better quality, our customers have to make less quality claims.

“The x-ray machine has already proven to be incredibly valuable, and I’m confident it will continue adding significant benefits to our production,” says Arttu Litja, Quality Engineer at Alsiva. “Its impact goes beyond Alsiva—other Ouneva Group companies can benefit from it too. Ours is the only Bosello Max machine in Finland!”

At Ouneva Group, quality is at the heart of everything we do. Our customers’ high standards inspire us to tackle these challenges. We embrace new technologies with curiosity and commitment, and the x-ray inspection machine is a perfect example of how we push boundaries to exceed expectations.