Parylene coating – Durable protection for demanding electronic applications

Protecting electronics is a crucial production phase during which the sensitive electronic parts of a product are shielded from various environmental and usage-related wear factors. In this article, we delve deeper into parylene coating. You can read about other electronic protection methods in our Electronics protection article.

Why is electronics protection important?

Electronic devices and almost all machines that drive our society contain some form of electronics. The general increase in the amount of electronics is evidenced by statistics on electronic waste. Poorly protected electronics often end up as waste, so it is also good to consider the environmental aspect in electronics protection.

Electronic components are sensitive to moisture, chemicals, heat, and mechanical stress. Protecting electronics extends the product’s lifespan and shields it from the aforementioned factors. High-quality protection reduces the risk of short circuits, corrosion, and other environmental damage to circuit boards and components. Protecting electronics also makes products less susceptible to interference. Practically, this means that products used in extremely challenging conditions can be trusted. Measuring devices, medical devices, and defense technology solutions are good examples of devices that must not experience any interference.

How does parylene coating work?

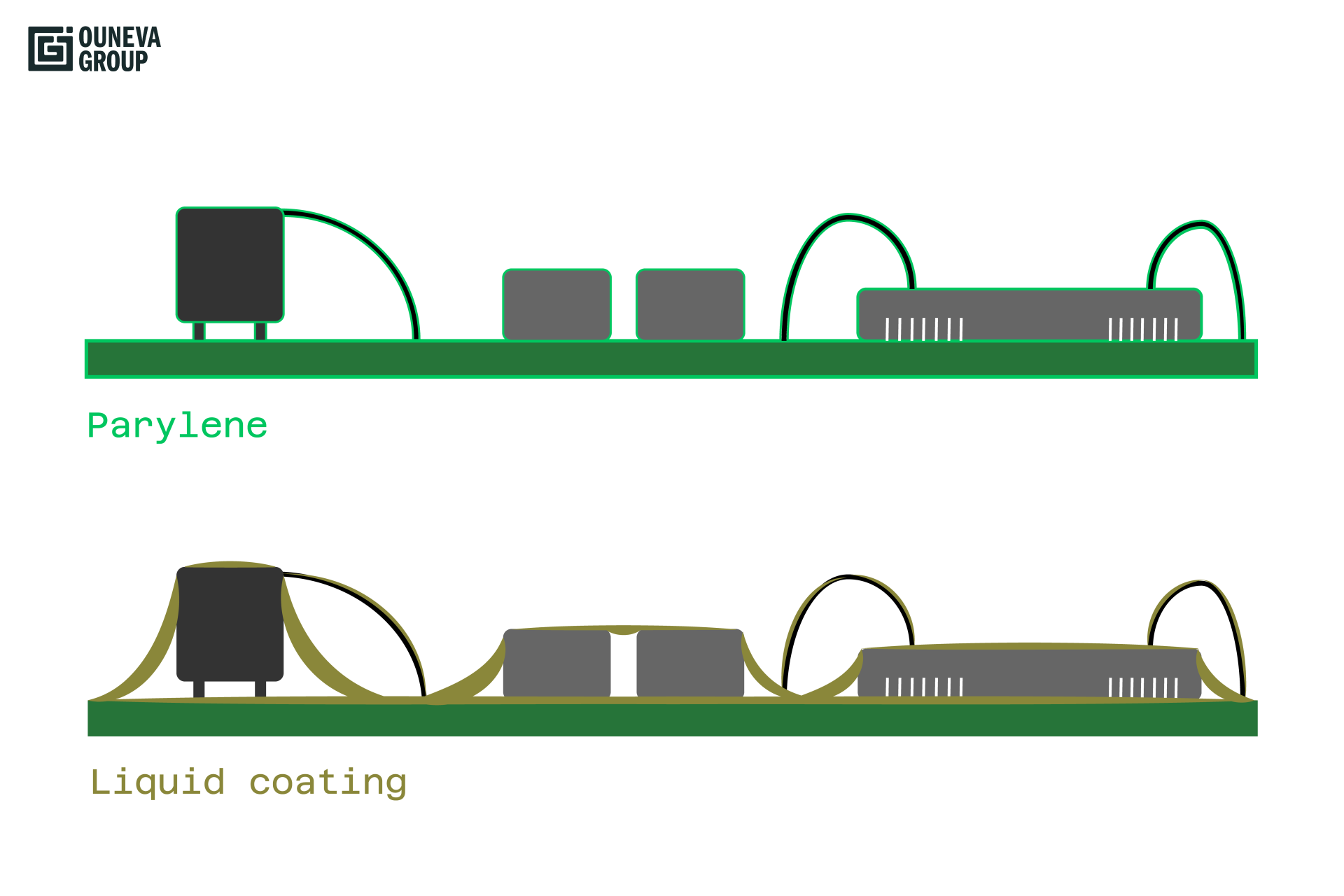

In parylene coating, a thin polymer film, 2-30 µm thick, is formed over, for example, a circuit board or sensor. The coating process itself is done in a vacuum chamber using specialized equipment. The polymer powder is vaporised in the equipment chamber and deposited to the desired thickness. As the parylene material is deposited, it forms a completely seamless coating. The deposition is done at room temperature, making parylene coating suitable for even the most sensitive products. The coating is deposited on all surfaces of the product with the same thickness, regardless of shape. Compared to conformal coating for example, parylene coating is a superior option due to its complete coverage. The equipment we use is located in a cleanroom and is designed to meet the strict requirements of cleanroom production. Ouneva Group was the first contract manufacturer in Finland to adopt the parylene coating technology.

Material information in brief

There are different types of parylene materials. The material is chosen based on the requirements of the product’s operating environment, but all parylene types (N, C, and D) have similar basic properties. These include:

- Hydrophobicity

- Chemical resistance (acids, bases, gases, water vapor)

- Electrical insulation

- Corrosion resistance

- Biocompatibility and biostability

Thanks to these basic properties, parylene coating is an excellent choice for products used in demanding environments. Biocompatibility ensures that parylene-coated electronic components can be used in medical devices, such as pacemakers. Biocompatibility also expands the range of applications to include, for example, the market for wearable smart devices. Excellent resistance to chemicals and moisture makes it suitable for the demanding needs of the defense industry. The corrosion resistance of parylene-coated products is very good. On average, parylene-coated products easily pass, for example, a 100-hour salt spray test.

Examples of applications suitable for parylene coating

- Circuit boards used outdoors or in challenging conditions

- Medical devices, such as pacemakers or implants

- Various sensors, for example, in the automotive or aerospace industry

- Optics and LED parts

Advantages of parylene coating

Parylene coating is a premium-level electronics protection method. Advantages compared to other more conventional protection methods include:

- Completely seamless, pinhole-free and uniform coating even on complex surfaces and densely packed circuit boards

- Does not add weight to the product

- Extremely thin protective layer

- Transparent

- Very durable

- Biocompatible

Quality assurance and standards

In the manufacture of sensitive electronic components, quality matters. Correctly chosen and high-quality protection for products reduces the risk of various defects and extends the product’s lifespan. Quality assurance for parylene-coated products is done by measuring the coating thickness and visual inspections. During the process, test strips are always inside the device, and analyzing the coating thickness, smoothness, and color of these strips serves as a quality assurance phase. An adhesion test is also performed on the coating. This test evaluates the adhesion of the coating according to the ISO 2409 standard. Parylene-coated products meet the stringent requirements of the defense industry’s IPC-CC-830B standard. Our experienced production staff ensures quality assurance for each coated batch.

Why invest in parylene coating?

Parylene coating is a worthwhile choice when your product is used in special conditions or needs to be particularly reliable. Expensive product defects or components damaged due to environmental factors can be avoided by choosing the right protection method. The excellent durability of parylene coating provides peace of mind regarding the aforementioned risks, as electronic components remain intact. From a responsibility perspective, more reliable products have a longer lifecycle, allowing the manufacturer to meet modern sustainability requirements and save the environment while at it.