Waste wood gets a new life

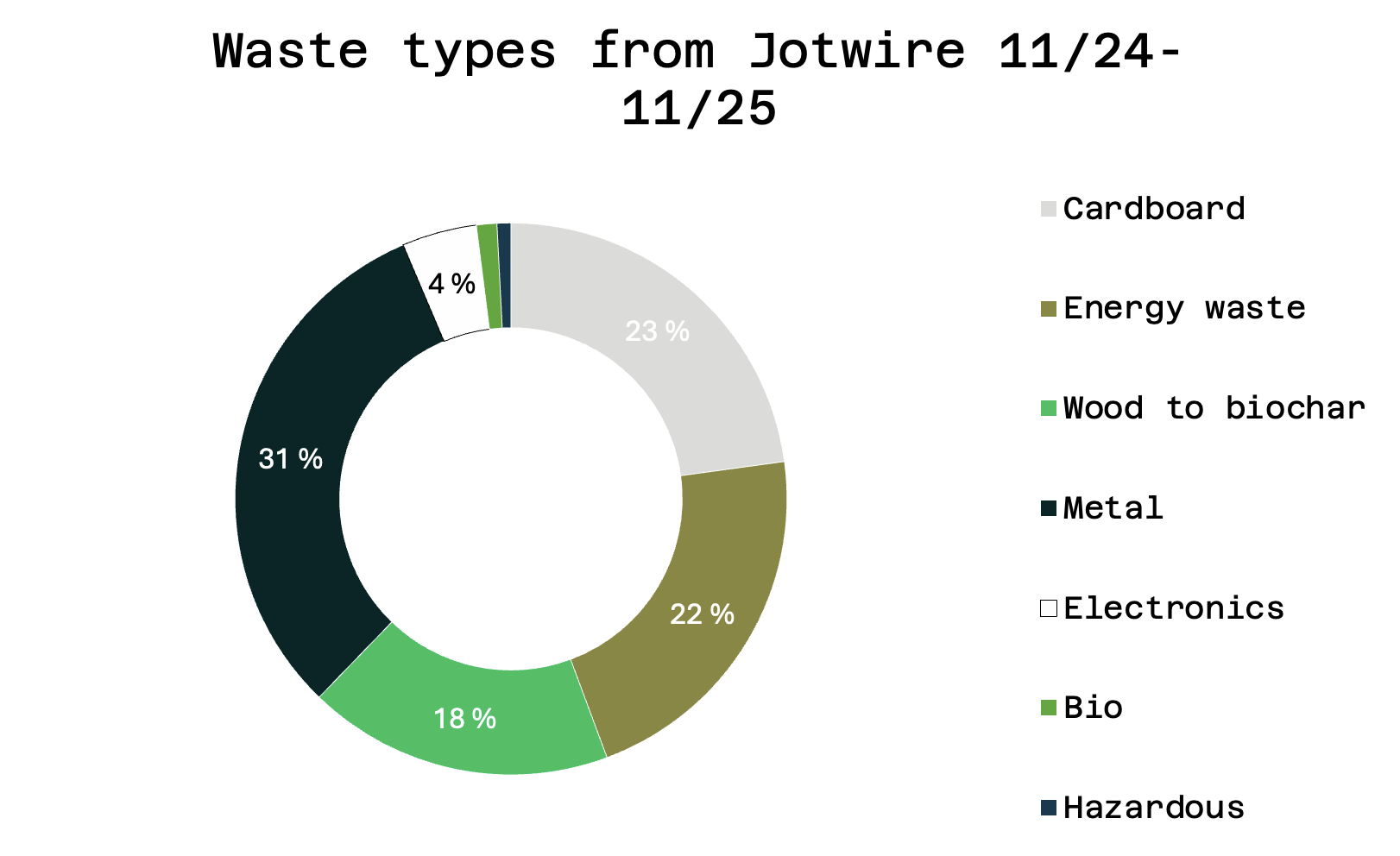

We are continuously working to improve our recycling rate in line with our responsibility strategy. Our development work includes, for example, increasing the possibilities for utilising different types of waste. Wood waste accounts for about 17 percent of the surplus material generated by Jotwire Oy. Because of this significant share, we wanted to find a recycling method that would allow the material to be used as a raw material instead of simply incinerating it for energy.

To help and partner with us in recycling wood waste, we teamed up with Karelian Paju, a company based in Kontiolahti specialising in biochar production. Karelian Paju receives Jotwire’s wood waste and transforms the material into biochar. In biochar production, waste wood becomes a new product with new applications.

Biochar is produced from wood using a pyrolysis process. After crushing and removing metals, the wood material is transferred to the pyrolysis unit, where it is heated in an almost oxygen-free environment, causing the wood to carbonise. After carbonisation, the material is cooled, any remaining metals are removed and it is ground into different textures. The finest, powder-like textures are suitable for use in cosmetics or even as a substitute for carbon black. Coarser textures can be used in a variety of ways, for example as filter material, in stormwater structures and as a soil improver.

We visited Karelian Paju’s production facility in November. A grey day turned out to be inspiring, as the applications for biochar are diverse and the material’s carbon sequestration over its lifecycle is exceptionally high. The Karelian Paju team presented the biochar production process, the end product’s uses and various visions for the future of biochar.

For Ouneva Group, cooperation with Karelian Paju has been smooth. We see it as a positive that we can genuinely utilise the surplus material generated in our production. Jotwire produces wood waste, for example from pallets and cable reels, which arrive at our factory as packaging for raw materials. Some of the pallets are reused as they are at Jotwire and in other Ouneva Group companies, but especially for cable reels, there has not previously been a straightforward recycling solution that would allow the material to be repurposed.

Our ability to influence includes ensuring the recycling of material, and we have been satisfied with our solution. The local nature of Karelian Paju was also a positive factor in choosing a partner. This way, our surplus material does not generate additional emissions, for example due to long transport distances.

More information about the sustainability strategy of Ouneva Group can be found on our Sustainability page.