Streamlining your supply chain-how does that work?

Rethinking a whole supply chain sounds like an unpleasant project for many people. The questions are endless, ranging from a simple why would I do this to more complex topics like how will our delivery terms look like, how will we move production, what will it cost and so on. Rethinking and streamlining your supply chain is surely an investment of its own, but with a highly efficient, simple supply chain your company can get many rewarding benefits.

We wanted to provide you with some answers from our point of view on the possible questions and to encourage people to rethink their complex supply chains. When we talk about supply chain management, simplicity is beautiful. Relying on as few suppliers as possible minimizes the risk of the chain breaking, for example because only one part cannot be delivered on time to the next link in the chain. A smaller number of suppliers also provides diversity for development and strategic aspects in the supply chain.

Especially now, since a lot of companies are moving their manufacturing away from the Far East, it is time to rethink the complex supply chains that we traditionally might be used to. Surely, risk management with moderate decentralization makes sense, but cutting up the supply chain and spreading it out widely provides more possibilities for failures between the numerous links. In the end, the goal is that no component or material is dependent on one supplier but on the other hand, every supplier can be utilized to the max.

Why would I rethink my whole supply chain?

Many companies are reacting to the changes happening in our economies and on our planet, and not all of it is bad, quite the contrary. Climate change challenges companies to become more sustainable, trade wars and tariffs are complicating the trade with low-cost countries and the global pandemic has shown how critical efficient supply chains actually are to companies, whether it be small or large. A lot of large multinationals are starting to realise how dependent they are on deliveries from the other side of the world. Is the risk management really working? Let’s take a look on some of the issues, that a streamlined supply chain might help to solve.

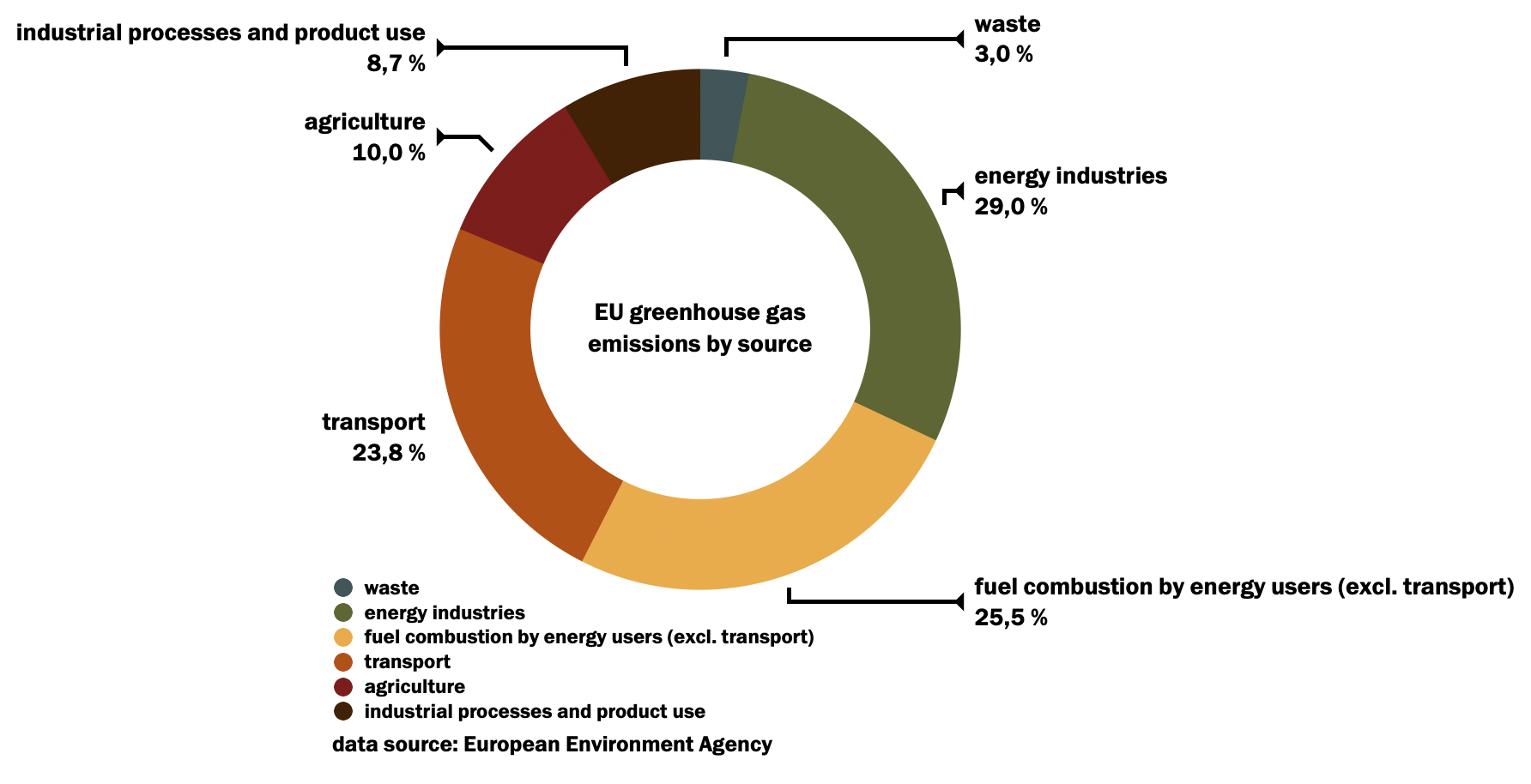

Companies especially in the manufacturing industry account for a big part of the global greenhouse gas emissions, and to be able to stay in business, things cannot go on with the “business as usual” mindset. The current pandemic situation has been a wake-up call about many issues, including climate change. As it has been projected, this pandemic will not be the last that we as a humanity will have to survive. From a financial point of view, in the future it might make sense to centralise manufacturing to those areas, where the pandemics have been survived well, socially and economically. In the figure below, you can find some data about where greenhouse emissions in the EU come from. The share of industrial processes is quite low by itself, but when we think about the bigger picture and how complex industrial manufacturing is, we start getting to the point where the 8,7 per cents start to expand into waste, energy industries and well as transport and energy usage.

Reducing the carbon footprint of companies is a hot topic at the moment. And we don’t think that environmental issues are going to just solve themselves. Thinking from the environmental perspective, it makes all of the sense to buy more local or at least closer from home to reduce transport emissions, as well as costs at the same time. Buying from fewer companies closer to home again reduces the carbon footprint of the product and the quality control is more straightforward with less links in the chain. The higher quality your products are, the less procedures that might grow the footprint after manufacturing will exist.

Corporate social responsibility issues come into play as well. It is a lot easier to know, how your suppliers are doing with their corporate social responsibility strategies and how well things are, when you have the opportunity to be in a close partnership. In industrial manufacturing, chemical use if a topic often talked a lot about in the news, for example a company spilling their hazardous waste into a field. For us, we wanted to take a closer look into the RoHS and REACH directives, since they touch our operations closely. Compliance with the RoHS and REACH directives give clear guidelines and restrictions on using hazardous chemicals. In short, the RoHS directive restricts the use of certain harmful substances in electronics and electrical appliances. The REACH directive on the other hand considers the responsibility of using hazardous chemicals, that can be harmful for the environment, as well as human health. Complying with REACH means that the company has a lot of independent responsibility in their health and safety management considering the chemicals they are using in their production. Complying with these directives is a clear advantage for corporate responsibility, and it should be a top priority when considering new partners. Committing to working against child labour should be included in the Code of Conduct of responsible companies. Auditing and monitoring suppliers are important tasks in the fight against child labour. At Ouneva Group, we comply with the RoHS & REACH directives, and we ensure that our suppliers are not using child labour with regular audits.

Since investors are becoming increasingly interested in the ESG (environmental and social governance) criteria in addition to a healthy return on investment, your profitability will look a whole lot better when you have a strong supply chain with clear ESG policies. The financial risk your company poses to a potential investor is smaller when your company has clear and fair ESG criteria in place! ESG links to all of the social responsibility issues mentioned above.

Streamlining the supply chain provides you with the assurance, that your agreed delivery times will be what they were promised to be. The efficiency in delivery comes from a partner with an established and reliable network of their own, which is why choosing a partner is so essential. When working with less suppliers, growing volumes give more negotiation power to both sides, which usually leads to better cooperation. Talking about cooperation and negotiation, a streamlined supply chain usually removes or at least minimizes the amount of time spent on supply chain governance compared to a traditional supply chain, where the links are very separate and even different. Less time is spent on monitoring the supply chain, more time spent on your own business functions.

Many companies have noticed that the reaction time and the risks considering their deliveries from countries like China are not feasible for their business, hence the interest in moving production into Western countries. Another challenge that might arise from expensive and long deliveries is that the amounts purchased should be very large in terms of cost effectiveness. When the delivery starts from closer to home, there is more flexibility in order amounts, delivery times, communication and collaborative development! Financially, there will be less capital tied to the delivery itself, the delivery times will be shorter and again, smaller risks related to the purchase.

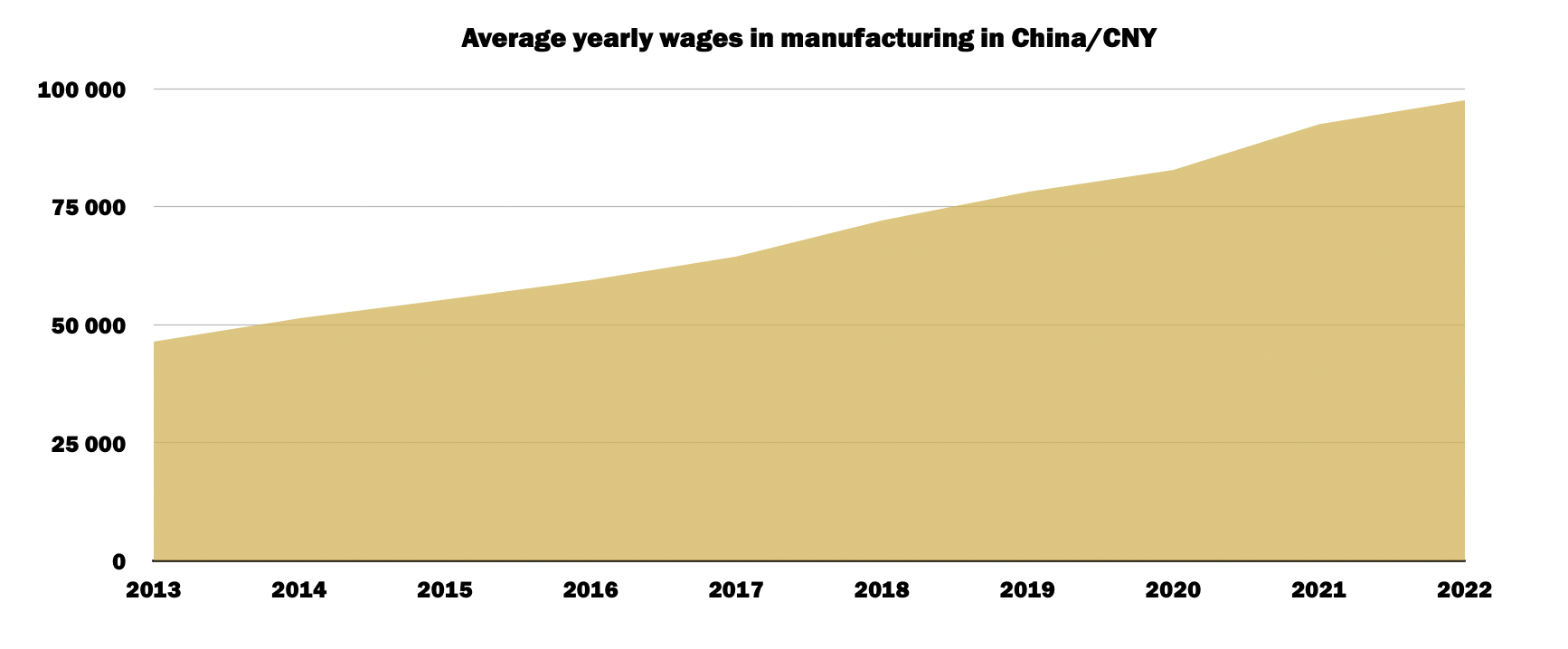

This chart depicts the development of yearly wages in manufacturing in China. A clear rising trend can be seen, and again, the trend is unlikely to change its course. The average wages are clearly lower than in Europe, which does not immediately mean that production in China would be more profitable, when taking a look at the bigger picture. Taking a note of China’s “Made in China 2025” agenda that was released already in 2015, the trend of China moving away from being a cheap, low-cost country into a high-tech pioneer is very realistic. In the future, it might be so that manufacturing in China is becoming more expensive as years go by. The MIC2025 agenda also gives the picture, that domestic production will be backed by the state to be become self-sufficient, which again makes the entering for global players very difficult. Source: Trading Economics.

Due to the Covid-19 pandemic, the freight costs saw a sharp rise. The prices per container have stabilised since then, but the market saw even quadrupled prices for some months in 2022. This raises the question if businesses are ready for such a sudden and strong increase in their logistics costs. This also supports the idea of having your production closer to your end market. Local shipping can be more efficient and lower in costs with less risks in this scale that the international container freight industry saw. Worldwide trends are hard to predict and we cannot know what could cause the next aggressive spike in international logistics costs.

Opportunities for innovation, as well as R&D are limitless with a good partner. When creating a good relationship with your supply chain partner, the partnership might motivate you to collaborate on research and new innovations together. The thing about business relationships that makes them so interesting, is that they can be quite similar to a relationship in your personal life. You grow and develop together and work like a team. In the end, we are all just people doing business, with other people!

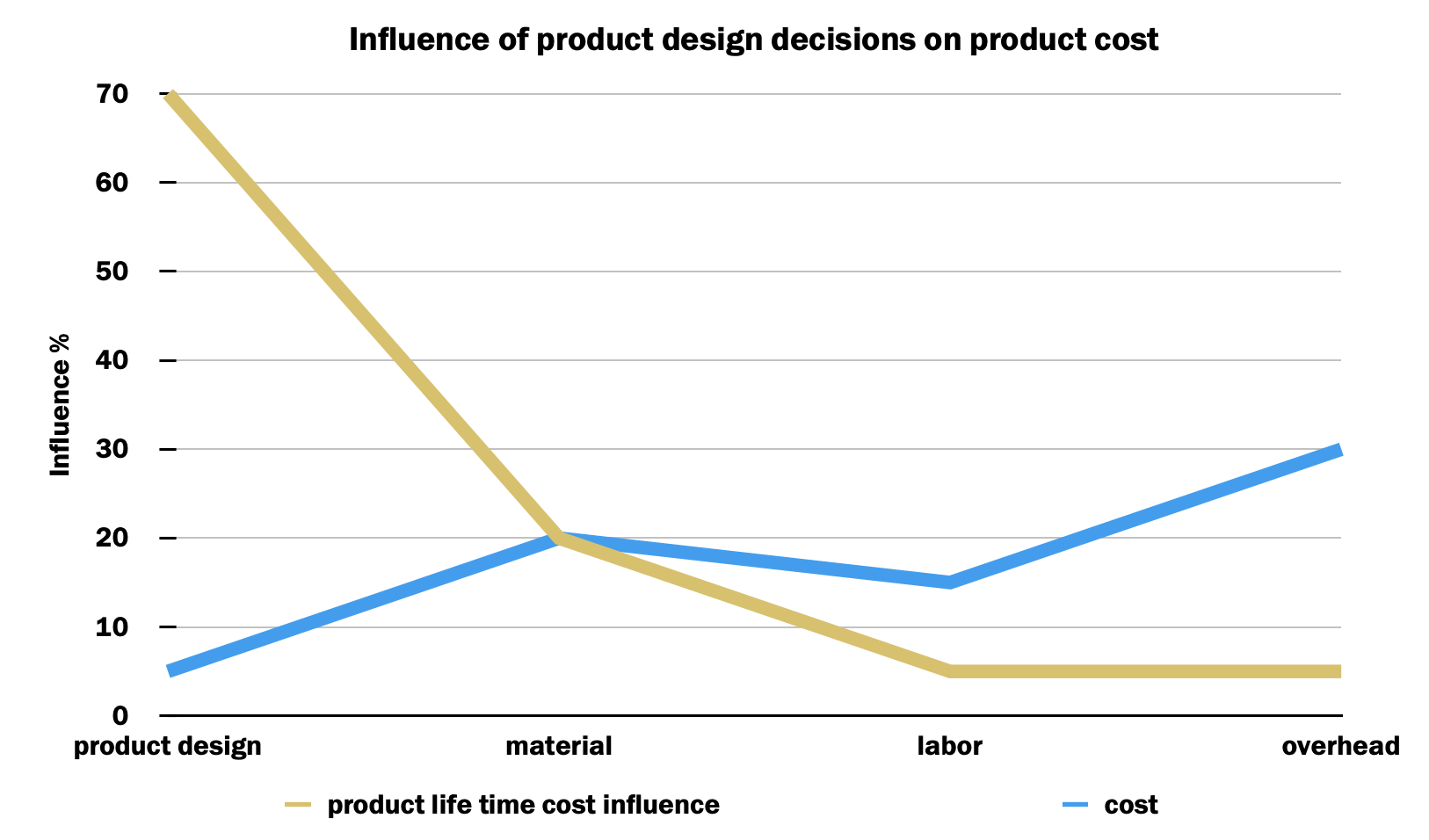

Product design is an important part of collaboration and it provides a lot of opportunities for reducing the overall costs of the products. The product design stage can define up to 70-80 % of the overall costs of the product, even though it is thought as only a small part in the product lifecycle.

In the design stage, some of the most important design choices regarding materials, manufacturability and product lifetime will be made. Even the labour costs related to the product in question can change drastically, due to the manufacturability and how skilled the workforce has to be. Building products with automated manufacturing in mind can be helpful to keep the costs down. These choices define the overall costs far in the line. This is why it is important to establish collaboration with partners, that are ready to proactively develop the product and that are able to provide diverse technologies. Please take note, that the data we used to visualise the influence and the overall costs are rough averages. They still provide a nice visual example of how important the product design stage is, applying to any manufacturing!

The ability to provide design for manufacturing (DFM) and design for assembly (DFA) services is a great advantage in managing the lifecycle costs of your product, especially in the case of contract manufacturers. Sometimes, their knowledge and expertise in providing streamlined services like those surpasses your own, and that’s nothing to feel bad about. Knowledge in different materials and manufacturing methods is best when it’s shared between you and your partner! Take it as an opportunity for a symbiosis, where expertise can be shared in both ways.

What benefits does a streamlined supply chain offer?

-CO2-emission reductions due to less transportation during the lifecycle of the product

-simpler operational model due to less links in the supply chain

-better accountability due to easier management of less links

-better understanding of the cost-factor associated to risks

-diverse development opportunities

-engaging partnership

-process cost savings in many areas

-improved corporate responsibility management

-more time for other activities (R&D, marketing etc) within the company due to less time spent administering the supply chain

-shorter lead time from product design to the market

-ensures ESG goals

To achieve all of these attractive benefits, the future partner/s in your improved supply chain must be carefully chosen. To help you in the process, we compiled a checklist of the most important things to keep in mind, when looking into your supply chain’s possible new partners. The comments are from procurement specialists inside Ouneva Group.

Matters to consider when choosing a supply chain partner

-The organizations you are considering are always developing their operations

-They have a strategy for corporate social responsibility

-They bring you extra value with technical support and technology news of your industry

-Their reliability (NDAs and other contractual matters are handled well, the number of claims is low, delivery percentage is >98 %)

-Their existing logistics network is good

-They are willing to develop your customer relationship actively

-The partner is proactive for example with suggesting better components or materials

-The partner is proactively suggesting new and more efficient manufacturing technologies

Make sure that the possible new partner is ready to fulfill and exceed the requirements of the procurement strategy of your organization! This will get you a long way.

Finally, we wish you best of luck in finding a manufacturing partner that fits your needs, and who is ready to exceed your expectations. At the same time, if you think we would be a good partner for you, please do not hesitate to get in touch with us through this form: contact us